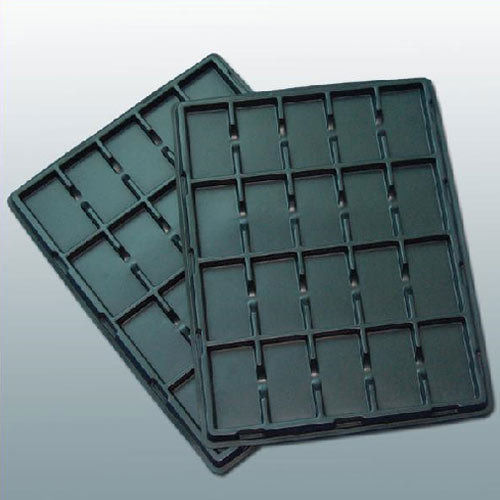

EPE Foam Fitments

50 INR/Piece

Product Details:

- Product Type EPE Foam Fitments

- Material Expanded Polyethylene (EPE) Foam

- Application Packaging, Cushioning, Protection of Fragile Items

- Surface Resistance Non-conductive

- Usage Shock Absorption, Impact Protection in Transit

- Size Customizable as per requirement

- Dimension (L*W*H) Available in Various Sizes, Custom to Application

- Click to View more

X

EPE Foam Fitments Price And Quantity

- 50 INR/Piece

- 100 Piece

- 50.00 - 500.00 INR/Piece

- Minimal/Closed Cell Structure

- Low, Offers Insulation

- Non-flammable/Available with flame-retardant grade on request

- Good suitable for Flexible Packaging

- Molded/Die-cut as per Product Requirement

- -40C to +70C

- Meets Standard Packaging Industry Norms

- Yes

- Odorless

- CFC and HCFC Free

- Excellent, Easily Molded or Cut

- 18 kg/m to 40 kg/m (can be customized)

- Smooth, Non-abrasive Surface

EPE Foam Fitments Product Specifications

- Available in Various Sizes, Custom to Application

- Shock Absorption, Impact Protection in Transit

- EPE Foam Fitments

- White (Other Colors Available on Request)

- Expanded Polyethylene (EPE) Foam

- Lightweight (varies as per size and density)

- Customizable as per requirement

- Packaging, Cushioning, Protection of Fragile Items

- Non-conductive

- Minimal/Closed Cell Structure

- Low, Offers Insulation

- Non-flammable/Available with flame-retardant grade on request

- Good suitable for Flexible Packaging

- Molded/Die-cut as per Product Requirement

- -40C to +70C

- Meets Standard Packaging Industry Norms

- Yes

- Odorless

- CFC and HCFC Free

- Excellent, Easily Molded or Cut

- 18 kg/m to 40 kg/m (can be customized)

- Smooth, Non-abrasive Surface

EPE Foam Fitments Trade Information

- 1000 Piece Per Day

- 3-4 Days

Product Description

Since 1993, our company is involved in manufacturing and supplying EPE Foam Fitments. These fitments are made by our experts using high-grade EPE foam in accordance with set industry norms. They are known for their high flexibility, impact & shock absorption nature. Provided fitments are widely demanded in the packaging industry for packaging of different products such as chemical vials, decorative pieces, and imitation jewelry. Before final dispatch, they are checked on different standard parameters such as quality and durability. These fitments ensure complete protection of packed products from outer impacts. EPE Foam Fitments are also available in different colors, sizes, shapes, and finishes.

Features of EPE Foam Fitments:

1) Effectively and efficiently cater to the needs of packaging industries.2) The fitments offer a tight hold and do not let the things to fall.

3) A sturdy configuration that meets the expectations of users.

4) Cost effective as well as dependable.

Exceptional Shock Absorption and Protection

EPE Foam Fitments provide reliable cushioning and impact protection for delicate products during transit. Their closed cell structure minimizes water ingress and enhances shock absorption, making them perfect for securing electronics, glassware, and other fragile items. These fitments significantly reduce the risk of damage throughout the supply chain, improving overall shipment safety.

Highly Customizable for All Applications

Our foam fitments can be molded or die-cut into various shapes and sizes as per your products unique requirements. With densities ranging between 18 kg/m and 40 kg/m, EPE Foam is versatile enough to accommodate packaging, insulation, and protection needs for industries such as electronics, automotive, and home appliances. Custom color and flame-retardant grades are also available on request.

Environmentally Responsible and Industry Compliant

EPE Foam Fitments are recyclable, CFC and HCFC free, and meet the standard norms of the packaging industry. The materials non-flammable or flame-retardant options ensure safety in application, while its odorless, non-abrasive nature guarantees the integrity of sensitive products. Clients can feel confident in their environmental responsibility with every use.

FAQs of EPE Foam Fitments:

Q: How are EPE Foam Fitments manufactured to suit specific product requirements?

A: EPE Foam Fitments are produced through either molding or die-cutting processes, allowing precise customization in shape, size, and density. Clients provide their specific dimensions and application needs, and manufacturers create fitments that ensure perfect cushioning and protection for each unique product.Q: What are the main benefits of using EPE Foam Fitments for packaging and protection?

A: These fitments offer excellent shock absorption, low water absorption, and good tensile strength. Being lightweight, flexible, and non-abrasive, they ensure safe transport of fragile items. Their closed-cell structure enhances durability, while for added environmental responsibility, they are recyclable and free from CFCs and HCFCs.Q: When should flame-retardant grades of EPE Foam Fitments be used?

A: Flame-retardant EPE Foam Fitments are recommended for applications where enhanced fire safety is crucial, such as in electrical or high-risk environments. They are available on request and comply with standard packaging industry norms for safety and performance.Q: What is the process to customize EPE Foam Fitments for a particular application?

A: Clients provide specifications including shape, size, density, and any special requirements like color or fire resistance. Manufacturers use molding or die-cutting techniques to produce fitments tailored precisely to these needs, ensuring optimal protection and presentation.Q: Where can these EPE Foam Fitments be sourced or supplied in India?

A: EPE Foam Fitments are distributed widely across India by manufacturers, dealers, suppliers, wholesalers, and exporters. Clients simply need to specify their requirements to receive solutions tailored for their industry or packaging needs.Q: How does EPE Foams closed-cell structure benefit its usage as a packaging material?

A: The closed-cell structure of EPE Foam prevents water and moisture ingress, enhances thermal insulation, and increases durability. This ensures long-lasting protection for products, especially during transit and storage in variable environmental conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'ESD Material Handling Products' category

Mkt. Office Address

No 41, HIG, 7th Main, KHB Colony II Stage

Basaveshwaranagar, Bangalore - 560079

Phone : +91 80 2341174, 30615837.

No 41, HIG, 7th Main, KHB Colony II Stage

Basaveshwaranagar, Bangalore - 560079

Phone : +91 80 2341174, 30615837.

|

ELECTROTEK STATIC CONTROLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |